The Engineer – Advanced corrosion protection for automation and engineering industries

Corrosion is serious problem for industry and governments worldwide

Corrosion, in its many forms, costs both private and public sectors vast amounts of money to repair or replace mechanical, electrical and electronics components. While all metals corrode, due to various reasons, there is no simple or single solution to the overall corrosion problem. However, there are some very cost effective and proven ways to prevent corrosion and failures caused by corrosion, thereby reducing or eliminating associated costs and increasing safety, which should be of foremost importance in the mind set of any preventative maintenance programme manager.

Corrosion is an increasingly serious and costly problem that can lead to equipment failures which range from being an annoyance to being catastrophic. Failures caused by corrosion could and do lead to a direct failure of a component which could affect the entire system and can not only be very expensive in terms of down time to repair or replace but can also prove to be very costly in loss of productivity, and possibly the loss of human life.

The financial cost of corrosion accounts for between 3{1668a97e7bfe6d80c144078b89af180f360665b4ea188e6054b2f93f7302966b} to 6{1668a97e7bfe6d80c144078b89af180f360665b4ea188e6054b2f93f7302966b} of a country’s GNP [1] and a 2016 study by NACE International concluded that the annual global cost of corrosion amounts to USD 2.5 trillion [2]. These costs increase each year.

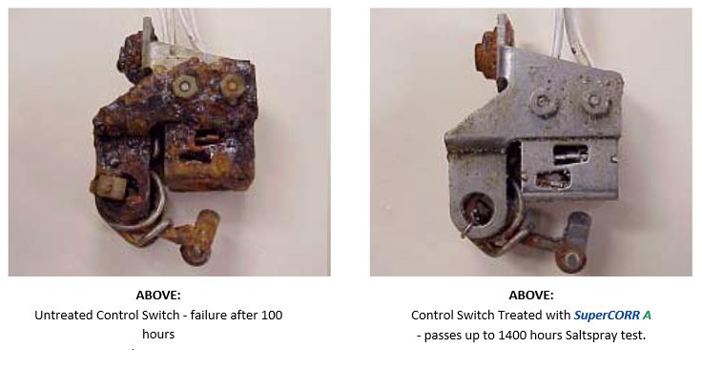

A vast amount of the annual cost of corrosion can be saved by using corrosion inhibitor products such as SuperCORR A which was specifically designed to lubricate and prevent corrosion in electrical fittings and connectors, electrical harness assemblies and connectors, electrical and electronic switches, close tolerance and dissimilar metal components, lighting connectors and sockets. It is a non-flammable “self-healing” ultra-thin film lubricant with a proprietary corrosion preventive compound that will not harden or crack. is not a wax or oil-based product and is formulated without sulphates, chlorides or halogens.

SuperCORR A is a unique and proprietary formulation with long-lasting, anti-corrosion inhibitors providing a superior lubrication coefficient and protection against moisture, wear, general and fretting corrosion, static electricity, corona, and other electro migration problems. The non-flammable film is only 7 microns (0.007mm) in thickness, is not a wax or oil-based product and is formulated without sulphates, chlorides, petroleum-based material, or halogens, to meet the EU RoHS directive.

Manufactured and supplied by EnviroTech Europe Ltd, it is unexcelled in preventing failures of electrical systems and electronic equipment caused by corrosion as well as preventing the corrosion of metal components surfaces. Use SuperCORR A to protect connectors, electrical systems and switches and mechanical controls during servicing. It’s ability to displace water from exposed contacts can ensure reliable operation in extreme conditions, all from one small aerosol can.

Prevent hydrogen sulphide corrosion in electrical and electronic equipment

Electrical and electronic equipment used in adverse work environments (e.g., the oil and gas, water treatment, pulp and paper industries) where corrosive gases such as hydrogen sulphide are found, can be particularly vulnerable to corrosion and lead to the rapid deterioration of the electronic components including mechanical controls, connectors and switches.

SuperCORR A inhibits corrosion caused by exposure to both fresh and salt water moisture as

well as the corrosive vapours from Sulphur dioxide (SO2), Nitrogen dioxide (NO2), Hydrogen

Sulphide (H2S), Ammonia (NH3), and Chlorine (CL12) based gases found in waste water and

sewer treatment plants, pulp and paper mills and plants, chemical and petroleum plants,

maritime industry, aircraft/airline industry, military equipment including ships, aircraft, and

rolling stock, auto industry, farming and agriculture industry, and the list goes on.

HFC-227ea gaseous fire suppression for electronic equipment.

When activated in a fire situation HFC-227ea will decompose to produce Hydrogen Fluoride. This is a real and ongoing concern. Why? Because Hydrogen Fluoride causes major corrosion problems for electronics and connectors. You may save your equipment but for how long?

To prevent corrosion caused by Hydrogen Fluoride, as well as other chemicals, acids, salts, and water which can be deposited during the activation of fire suppression systems or rapid humidity changes, all the electrical and electronic hardware, boards and connectors should be sprayed or coated with SuperCORR A. It will protect and prevent damage to the electronics or avionics caused by exposure to the Hydrogen Fluoride produced as a by-product during the fire.

Fretting corrosion on gas turbine connectors

LP Gas Turbines are used throughout the world by extraction industries and manufacturing

plants in remote and hostile locations for essential power production. Dusty and wet

environments in deserts, mines, grinding mills, pulp and paper mills and on land or sea drilling

rigs for gas and oil production. Turbines powering aircraft services while stationary connect and

disconnect many times a day in extreme conditions. These applications and locations test

connector sealing continuously allowing dust or water to penetrate. This with the flexing of the

connecting cables allows sufficient movement between the metal surfaces of the connecting

pins to produce fretting corrosion which reduces, interrupts or produces failures in

supply. Regular maintenance of electrical connectors is essential to be certain of uninterrupted

supply.

Containing extremely long-lasting, proprietary anti-corrosive inhibitors SuperCORR A provides a

superior lubrication coefficient and protects components against moisture, wear, general and

fretting corrosion, surface static electricity, corona, and other electromigration problems.

Avionic corrosion protection

SuperCORR A extends the working life of avionic harness assemblies, electrical systems and other critical items in aircraft maintenance by preventing the deterioration and/or failure caused by corrosion and can significantly reduce downtime, operating and maintenance costs as well as enhance safety. It has as undergone extensive testing by Battelle Labs as well as the U.S. Air Force and meets MIL-DTL-87177B (revised MIL-L-87177A) specification.

SuperCORR A is used by NATO (NATO NSN 8030-99-226-6966) to protect avionic electrical switches, sockets, connectors and components from corrosion in both the military and civilian aircraft. It is the global industry standard for electrical corrosion protection, for in service maintenance by both military and commercial aircraft major repair and overhaul (MRO) facilities.

Sea Spray exposure

Most people associate corrosion control with rust, which only happens in things made of ferrous metals such as steel girders, ships, iron pipes, steel reinforcement rods, and steel tanks and is the reason metals deteriorate and fail. Ferrous and non-ferrous metals corrode on contact with both fresh and saltwater as well as water vapour. They will also corrode when they come into contact with chemicals, liquid acids as well as acidic vapours, salts and bases, and bacteria.

The U.S. Navy selected SuperCORR A after exhaustive testing using American Society for Testing and Materials (ASTM) Standard B117- Standard Practice for Operating Salt Spray Apparatus.

SuperCORR A out-performed 11 other products in comparative testing to identify a better product to protect and lubricate the flap tracks and screw jacks on the aircraft. SuperCORR A was evaluated against competitive products under the Federal Test Method Standard #791B, using a five percent Salt Spray Corrosion Test.

ABOVE:

Mild Steel panel exposed to sea spray on board ship for 6 months.

A: Oil based CPC, B: Untreated section, C: Treated with SuperCORR A, demonstrating its superior performance.

The use of SuperCORR A in regular maintenance procedures can bring financial savings in reduced maintenance and replacement costs, and more importantly, greater safety.

Maintenance of contacts on portable gas generators

A leading manufacturer of connectors tested SuperCORR A to see what the “life” of the lubricant was in a “rub test”. The typical test is 20,000 cycles, i.e. unplug, plug in is one cycle. The test results demonstrated that after 20,000 cycles there were no failures. It was decided to take it one more step and run the same tests for 200,000 cycles. The results again showed no indications of galling or scoring on the connectors at all. The connector looked and tested as good as new. This test was run under clean conditions in a laboratory but demonstrates the effectiveness of the protective lubricant in SuperCORR A.

Unpainted metal in highly corrosive environments

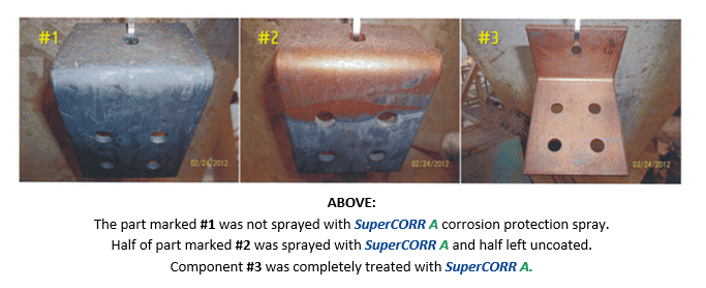

Tests demonstrate the amazing properties of SuperCORR A corrosion protection spray to protect unpainted metal surfaces from corrosion. These are photographs of 3 unpainted copper components that were exposed for a month next to the “digester” at a Pulp and Paper Mill.

The main atmospheric corrosion was from hydrogen sulphide (H2S) gas, produced during the cellulose digestion process, which combines with the atmospheric humidity to form a mild acid. Any unpainted or untreated metal surface, copper, brass, mild steel or alloys of zinc and manganese or magnesium will be corroded by this acid when it condenses on the metal surfaces.

CONCLUSION

It is clear the use of SuperCORR A for corrosion control can not only bring financial savings in reduced maintenance and replacement costs but more importantly greater safety. It is much simpler and a lot less costly to prevent corrosion than to repair or replace the damaged equipment or component that failed because of corrosion. As you have seen The photographs show the effects of protecting metal surfaces and components in extreme condition with SuperCORR A.

SuperCORR A is packaged in aerosol cans making access to component parts easy for engineering crews in difficult locations and conditions. Unpainted mild steel will not rust on exterior surfaces directly exposed to sea water environments for at least 6 months, protecting electrical connectors, switches, chains, drive shafts from corrosion while maintaining lubrication on moving surfaces.

EFFICIENT AND ECONOMICAL

- Extremely long-lasting, specially formulated and proprietary anti-corrosive inhibitor.

- Eliminates premature failure of components created by moisture, general or fretting corrosion.

- Prevents deterioration and contamination on all surfaces of electronic and electrical equipment and mechanical close tolerance moving components.

- Reliability increased, maintenance intervals increased and costs reduced, manufacturers save costly warranty service calls or product re-call.

APPROVED

- Industry approval from: NASA, Boeing Aircraft, Bombardier, Embraer, Lear, Gulfstream, Hawker-Beechcraft, Cessna, Raytheon, Polish Airforce, Northrop-Grumman, Royal Navy and Royal Norwegian Air Force.

- Exceeds Mil C 81309 Corrosion Prevention Compounds.

- Approved in US Tri-Service Corrosion Manuals.

FURTHER INFORMATION

Please visit our website https://www.envirotech-europe.com/supercorr-a for information about other uses and applications for SuperCORR A.

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact

form. All products are supplied and supported by EnviroTech Europe Ltd. Manufactured in the

United Kingdom and available on short delivery times through our dedicated team of

distributors worldwide.

References:

- https://heat-exchanger-world.com/featured-story-the-cost-of-corrosion-microbial-corrosion-in-heat-exchange

- http://impact.nace.org/economic-impact.aspx

Supplied and supported by

EnviroTech Europe Ltd

Aissela, 46 High Street, Esher, Surrey, KT10 9QY,

United Kingdom

Tel +44 (0) 20 8281 6370