How Online Training Is Changing the Way Industrial Engineers Learn

Image Source: saVRee.com

Industrial engineering has always focused on optimization: making systems, processes, and organizations more efficient, effective, reliable, and less costly. Industrial engineers have always had to master not just the foundation of engineering, but also complex tools, digital systems, and problem-solving methods that are needed to keep pace with industry.

Industrial engineering knowledge has traditionally been acquired through formal post-secondary educational institutions, textbooks, and workplace training. That said, there has always been some type of digital/technology-assisted engineering education; however, in today’s world, digital/technology-assisted engineering education has transformed the way engineers learn. With the increasing use of online industrial engineering courses, students and professionals now have access to a flexible and interactive form of training and can learn about areas that focus closely on their industry sector, and assist them in solving complex problems that they may face after their training.

In this post, we will look at the way online training is changing industrial engineering learning, identify advantages over traditional approaches, and ultimately reflect on how online learning programs, such as saVRee, can help the industrial engineering profession move forward.

The Traditional Approach to Industrial Engineering Education

For decades, industrial engineers have been trained primarily through academic programs. These include structured courses in operations research, manufacturing systems, logistics, quality management, and human factors.

Strengths of traditional training include:

- Accreditation and Structure: University degrees provide formal recognition and a standardized curriculum.

- Face-to-Face Interaction: Direct access to professors and peer discussions.

- Hands-On Labs: Opportunities to experiment with physical systems and simulations.

Limitations of traditional training:

- High Costs: Tuition fees, lab expenses, and textbooks are significant.

- Limited Flexibility: Students must adhere to fixed schedules and physical locations.

- Curriculum Gaps: Academic programs often lag industry trends, leaving graduates under prepared for the demands of the workplace.

- Access Barriers: Not all learners worldwide can afford or access quality industrial engineering programs.

While universities remain vital for foundational learning, they often struggle to keep pace with the rapid pace of industrial transformation.

The Shift Toward Online Industrial Engineering Learning

In the wake of the digital revolution, education has shifted across disciplines (including industrial engineering). Today, online education allows students to learn many of the fundamentals of industrial engineering (systems optimization, process engineering, lean manufacturing, industrial equipment design) without ever visiting a traditional classroom.

Advantages of Online Training for Industrial Engineers

- Flexibility and Access

The flexibility of online courses enables learners to study anywhere and anytime. This is especially beneficial for working service sector professionals looking to hone their skills without a career disruption. Additionally, students can pause, replay, revisit, and review complex areas of study at their own pace.

- Relevant Industry Content

Online courses are relevant to industry, as opposed to many of the traditional programs that remain unchanged for years, as they complete a full curriculum review. Online training is frequently refreshed with emerging industry practices, tools, and standards to ensure that learners are studying relevant content.

- Visual and Interactive Learning

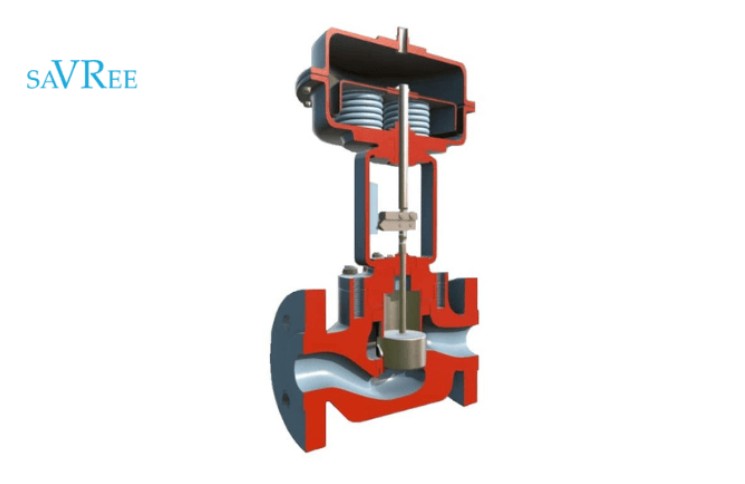

Textbooks and static diagrams rarely capture the complexity of industrial systems. Platforms like saVRee offer students 3D models, animations, and interactive diagrams, allowing them to explore machinery, processes, and systems from a virtual perspective.

- Cost-Effective

Online training removes commuting, relocation, and infrastructure costs while delivering high-quality education at a fraction of the cost. It also helps democratize access to industrial engineering education anywhere in the world.

- Lifelong Learning and Upskilling

Engineering careers require continuous development. These online courses help with continuous professional development, allowing engineers to improve their learning abilities and adapt to new technologies, like automation, AI-driven optimization, and smart manufacturing.

Traditional vs. Online Training: A Comparison

Traditional Training

- Delivery Method: In-person tutorials, handbooks, and hands-on work

- Flexibility: Designed schedules, location-limited

- Industry Relevance: Curriculum tends to be outdated when skills are transferred

- Accessibility: Focused on enrolled students in recognized institutions

- Cost: Increased tuition, building, and material costs

- Retention: Passive learning by way of lectures

Online Training

- Delivery Method: Online lessons, 3D models, and interactions, simulations

- Flexibility: Anytime, anywhere, at own pace

- Industry Relevance: Regularly Updated to real-world applications

- Accessibility: Accessible to anyone with an internet connection at any location

- Cost: Fair pricing, scalable, subscription-based access

- Retention: Active learning by way of visuals and interactions

Both Training approaches are worthwhile; however, online training offers organizations a much more flexible and scalable option for today’s rapidly changing industry.

How 3D Visuals Enhance Industrial Engineering Education

Industrial engineers face complexities related to systems — assembly lines, supply chains, robotics, quality control devices, etc. They typically have to understand these systems from static images or animations.

3D visuals support the learning revolutionize by:

- Dissecting machinery into its constituent parts so they can be analyzed in detail.

- Simulating processes and providing visuals to show how systems work in a variety of situations.

- Providing virtual tours of industrial plants, logistics systems, and manufacturing processes.

- Providing more relevant content by connecting theory to practice so the learner can see how theory (like formulae) is reflected in reality.

saVRee and similar platforms take advantage of these tools to engage learners and help the components make sense.

The Role of saVRee in Industrial Engineering Training

saVRee has emerged as an authority in the provision of online industrial engineering-based training that combines theory with active, visual learning.

The highlights of saVRee training include:

- 3D Models and Animations: In an engaging way, learners can explore industrial equipment and processes.

- Wide Course Coverage: From mechanical systems to electrical and industrial processes, saVRee has a significant number of engineering topics covered.

- Enterprise Training Solutions: saVRee provides a solution for organizations to engage and enhance the skills of entire departments.

- Worldwide Access: Anyone with internet access can learn, regardless of geographical limitations.

saVRee combines rigorous standards with an innovative delivery method to provide learners with the best possibility of learning the skills they need to be successful in both educational and professional contexts.

Why Online Training Is the Future for Industrial Engineers

The industrial engineering profession is rapidly changing due to digital transformation, smart factories, and sustainability. Online training safeguards engineers against that future by:

- Falling in line with technological change, allowing engineers to access updated, on-demand courses.

- Supporting hybrid learning, leveraging the best aspects of traditional learning away from online offerings.

- Supporting global learners with accessibility to institutions of high quality who may not otherwise have support for this learning.

- Encouraging continuous improvement, similar to the ideals of industrial engineering.

In summary, online training is efficient, optimized, and flexible – and fits the definition of industrial engineering.

Final Thoughts

Industrial engineering is fundamentally concerned with improving systems and processes, and the learning process for industrial engineers is no different. Online training is changing the game through more flexibility, lower cost, and better relevance.

By taking online industrial engineering courses from saVRee, students and professionals alike can experience online education through online content, on-demand material, and industry-relevant information that provides insights and knowledge to deal with real-life challenges.

The future of learning in industrial engineering will not be based on textbooks alone. The future will entail a combination of ‘old school’ learning blended with the potential of ‘new school’ digital technology, and the core will be online training. For professional engineers and/or students wanting to remain relevant, online training is paramount.